The book follows the Practical Short Course philosophy honed by 25 years of teaching technical processing techniques at Texas A&M University. Nearly 8000 people have been trained through this program, many of whom hold positions of responsibility and stature in their companies and industry.

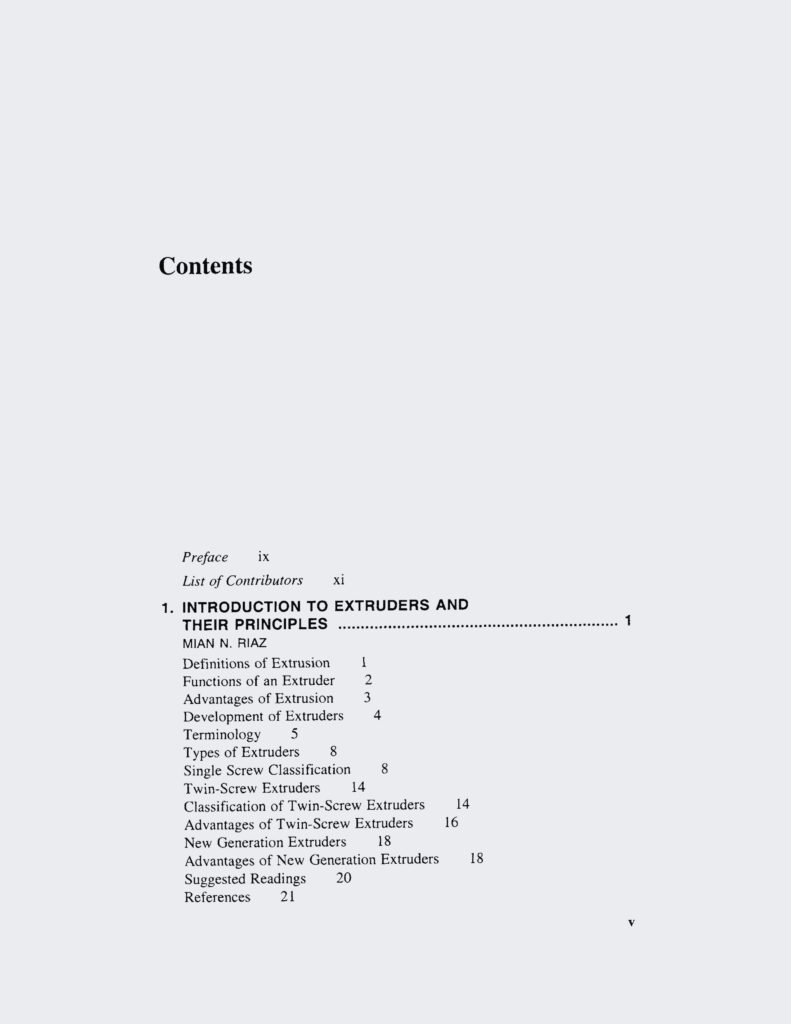

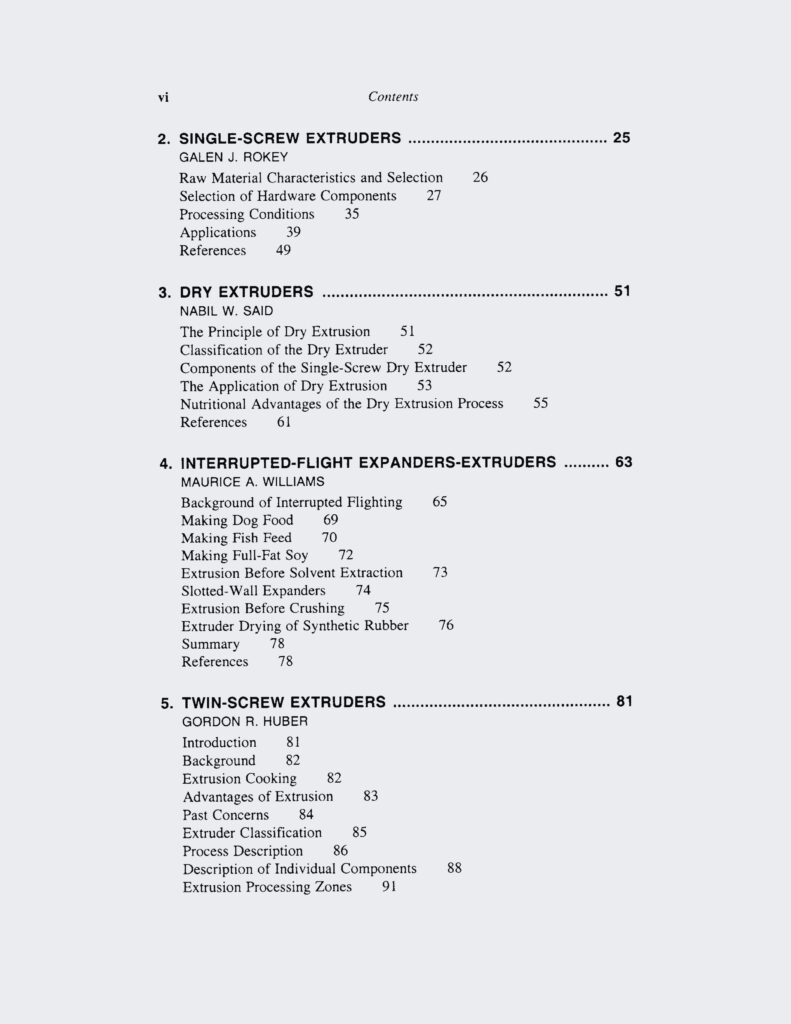

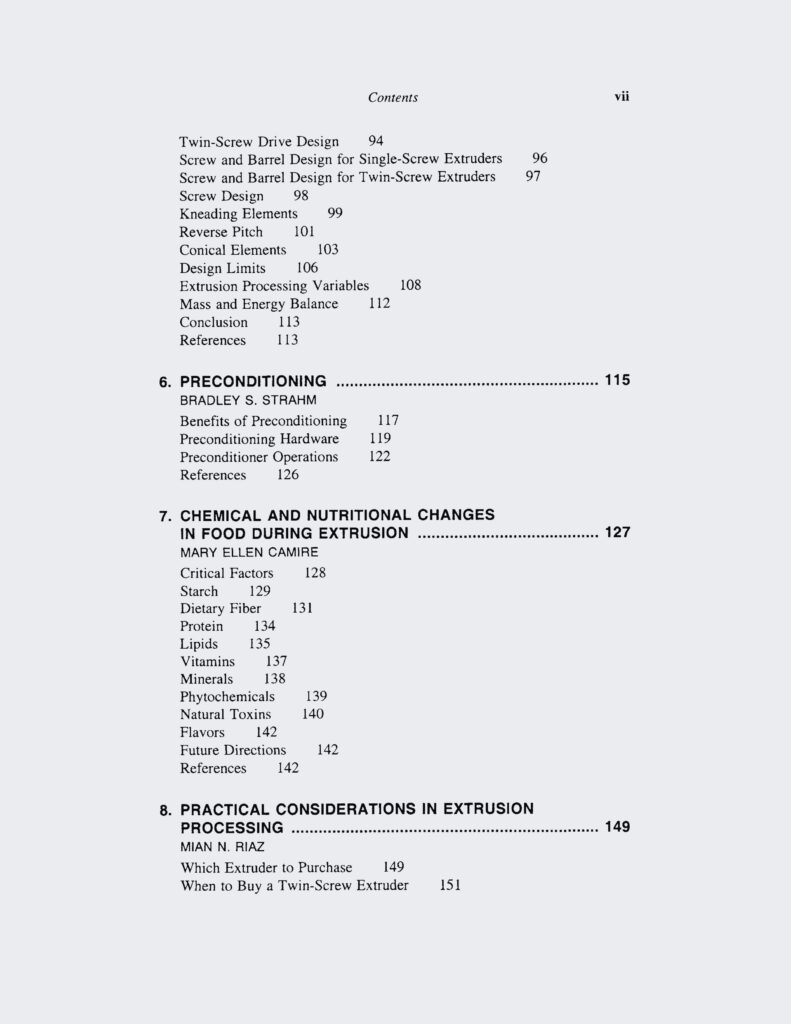

Chapters in this book are arranged in a procedural, top-to-bottom basis. First, different designs of extruders (dry, single, twin, universal pellet cooker) and expanders are discussed in detail. Raw materials (with their nutritional qualities), and processing characteristics are discussed in two separate chapters. There are chapters which discuss the pre- and post- extrusion process like grinding, drying and coating. Since more than 80% extrusion systems sold today comes with automation, a chapter is dedicated to operational automation and its benefits. Die design plays an important role in shapes, production, as well as creating floating and sinking characteristics in feed. Once feed is made, shelf life, palatability and microbial control are very important. The last chapter is focused on troubleshooting and extrusion operation.

This book is the result of practical experience in soybean industry and the contributors to this book have years of experience in their field. It serves as a source of information to those involved with the feed industry. For the newcomer, it is a guide for understanding extrusion, the proper selection of the raw ingredients, the operation of extrusion equipment, the processes involved in running an extended operation.